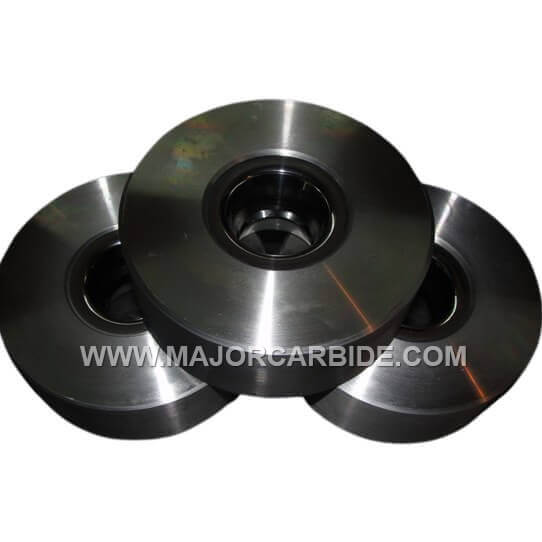

Carbide tube drawing dies

- high compressive strength, excellent wear resistance, good thermal conductivity

- close tolerance, high precision, long service life, high surface quality for drawn materials

- simple production, low cost, cost-effective application for drawn wire, bar, tube

- a large range of sizes, several grades for tungsten carbide dies nibs

- standard and shaped carbide dies available,supply carbide drawing dies with steel cases and without cases

Carbide tube drawing dies is a metalworking process used to reduce the cross section of ferrous and non-ferrous metal tubes. Tube, or pipe, drawing dies can be round, square, octagonal as well as any custom shapes desired. These dies are used for tube drawing such as copper, aluminum, steel, brass and copper alloys with a satisfactory surface finish. We also manufacture carbide floating plugs, carbide mandrels used to maintain the inner diameter of the pipe or tube.

The grade for cemented carbide drawing pellet

| Grade | Density g/cm3 | Hardness HRA | T.R.S N/mm3 | Application |

|---|---|---|---|---|

| YG3X | 15.1 | 92 | 1300 | For drawing steel wire, non-ferrous, and alloy wires with less than diameter 2mm. |

| YG6X | 14.95 | 91.5 | 1800 | For drawing steel wire, non-ferrous wires and bars with less than diameter 6mm. |

| YG6 | 14.95 | 90.5 | 1900 | For drawing steel wire and non-ferrous alloy bars of less than diameter 20mm, and drawing tubes of less than diameter 10mm. |

| YG8 | 14.8 | 89.5 | 2200 | For drawing steel, non-ferrous metal, and alloy bar&tube, it can also be used for machinery parts, tools, and wear parts. |

| YG10 | 14.5 | 88.5 | 2400 | For drawing steel rods,tupe&pipe with a high compression rate. |

| YG15 | 14 | 87 | 2800 | For drawing steel rods,tupe&pipe with a high compression rate. |

The sizes for tube drawing dies

| Type | D (mm) | H (mm) | Hole range d(mm) | Type | D (mm) | H (mm) | Hole range d(mm) |

|---|---|---|---|---|---|---|---|

| S20 | 38 | 28 | 17.5-18.5 | S23 | 50 | 32 | 20.0-24.0 |

| S20 | 40 | 25 | 21.5 | S23 | 60 | 35 | 26.0-30.0 |

| S20 | 45 | 28 | 25.5-26.5 | S23 | 70 | 42 | 32.0-36.0 |

| S20 | 50 | 30 | 27.5-30.5 | S23 | 75 | 42 | 38.0-40.0 |

| S21 | 50 | 35 | 20.0-24.0 | S23 | 85 | 45 | 42.0-46.0 |

| S21 | 60 | 45 | 26.0-30.0 | S23 | 100 | 50 | 48.0-54.0 |

| S21 | 70 | 45 | 32.0-40.0 | S23 | 110 | 50 | 56.0-62.0 |

| S21 | 80 | 45 | 42.0-46.0 | S23 | 125 | 55 | 64.0-70.0 |

| S21 | 90 | 45 | 48.0-54.0 | S30 | 23.5 | 16 | 12 |

| S21 | 100 | 45 | 58.0-62.0 | S30 | 24.5,25.5 | 16 | 14 |

| S22 | 20 | 13 | 2.8-5.7 | S30 | 25.5,27.5 | 16 | 14 |

| S22 | 30 | 18 | 6.7-11.5 | S30 | 28-36.4 | 27 | 17 |

| S22 | 45 | 24 | 12.5-23.5 | S30 | 37-39.4 | 27 | 19 |

| S22 | 50 | 25 | 24.5-30.5 | S30 | 40-43 | 27 | 21 |

| S22 | 60 | 30 | 24.0-33.5 | S30 | 44-46 | 32 | 23 |

| S22 | 65 | 32 | 34.5-39.5 | S30 | 47-53 | 32 | 25 |

| S22 | 70 | 35 | 34.5-35.5 | S30 | 54-57 | 32 | 28 |

| S22 | 75 | 35 | 40.5-42.5 | S30 | 58-64 | 35 | 28 |

| S22 | 80 | 35 | 34.5-47 | S31 | 14-16 | 25 | 7 |

| S22 | 85 | 40 | 47.5 | S31 | 17-18 | 25 | 8 |

| S22 | 90 | 40 | 46-53 | S31 | 19-22 | 30 | 10 |

| S22 | 100 | 40 | 55-57 | S31 | 23-27 | 30 | 12 |

| S22 | 120 | 45 | 59-67.0 | S31 | 28-42 | 35 | 16-20 |

| S22 | 130 | 50 | 69-77 | S31 | 43-44 | 40 | 22 |

| S22 | 140 | 50 | 79-88 | S31 | 45-50 | 45 | 26.4 |