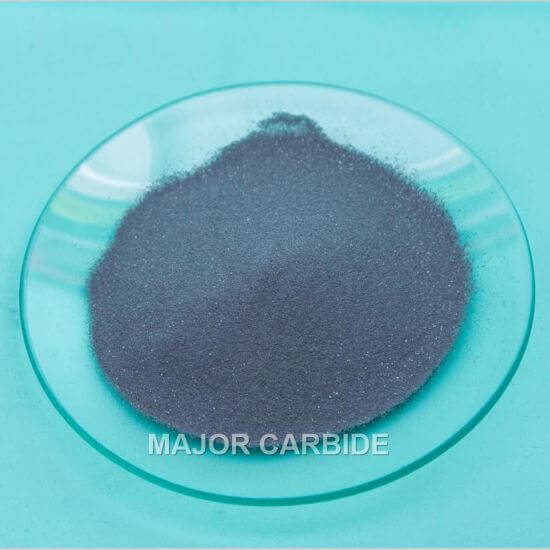

crystalline tungsten carbide powder

Appearance: dark grey powder with good flowability

Application: wear-resistance coating materials, cemented carbide materials, diamond drill and its cover in petroleum exploitation.

| Grade | YJ | ||

|---|---|---|---|

| Impurity Content% Max | T.C | 6.10±0.10 | |

| Impurity Content% Max | F.C | 0.10 | |

| Impurity Content% Max | Fe | 0.30 | |

| Impurity Content% Max | Ti | 0.10 | |

| Impurity Content% Max | Ta | 0.03 | |

| Impurity Content% Max | Mo | 0.10 | |

| Impurity Content% Max | Nb | 0.03 | |

| Impurity Content% Max | Si | 0.05 | |

| Impurity Content% Max | O | 0.20 | |

| Impurity Content% Max | W | balance | |

| sieve size: mesh | -60/+325, -60/+230, -200/+400 | ||

Crystalline tungsten carbide powder, acts as wear-resistant coat material, its hardness is only less than diamond. At present, it’s mainly used in the field of improving the wear-resistant performance of aviation and aerospace engine blade, driving gear, drive part, shaft and cemented carbide. It’s also mainly used in the field of rocket, thermal spray, jet, nuclear power and etc.