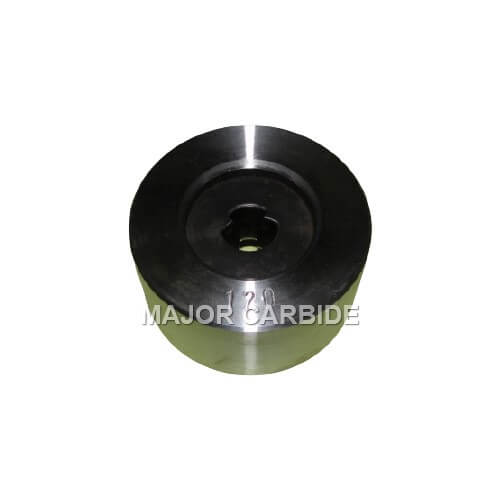

Carbide wire drawing dies

- high compressive strength, excellent wear resistance, good thermal conductivity

- close tolerance, high precision, long service life, high surface quality for drawn materials

- simple production, low cost, cost-effective application for drawn wire, bar, tube

- a large range of sizes, several grades for tungsten carbide dies nibs,micro-holes from 0.10mm

- standard and shaped carbide dies available, supply carbide drawing dies with steel cases and without cases

Carbide wire drawing dies are a wise economical choice for various ferrous and non-ferrous wire and bar drawing applications. The high compressive strength of tungsten carbide allows it to handle extreme pressure, making it ideal for use in drawing dies. For this reason, carbide dies are used in the drawing process by all major wire, rod, rope and tube manufacturers. Drawn materials include low, medium and high carbon steels, steel alloys, stainless steel, steel cord, welding wire as well as aluminum and copper alloys. We manufacture round, square, rectangle, hexagon carbide drawing dies, and intricate shapes die.

The grade for tungsten carbide wire drawing nibs

| Grade | Density g/cm3 | Hardness HRA | T.R.S N/mm3 | Application |

|---|---|---|---|---|

| YG3X | 15.1 | 92 | 1300 | For drawing steel wire, non-ferrous, and alloy wires with less than diameter 2mm. |

| YG6X | 14.95 | 91.5 | 1800 | For drawing steel wire, non-ferrous wires and bars with less than diameter 6mm. |

| YG6 | 14.95 | 90.5 | 1900 | For drawing steel wire and non-ferrous alloy bars of less than diameter 20mm, and drawing tubes of less than diameter 10mm. |

| YG8 | 14.8 | 89.5 | 2200 | For drawing steel, non-ferrous metal, and alloy bar&tube, it can also be used for machinery parts, tools, and wear parts. |

| YG10 | 14.5 | 88.5 | 2400 | For drawing steel rods,tupe&pipe with a high compression rate. |

| YG15 | 14 | 87 | 2800 | For drawing steel rods,tupe&pipe with a high compression rate. |

The sizes for tc wire drawing dies

| Type | Nib D(mm) | Nib H(mm) | Hole range d(mm) | Type | Nib D(mm) | Nib H(mm) | Hole range d(mm) |

|---|---|---|---|---|---|---|---|

| S01 | 6 | 4 | 0.2,0.8 | W101 | 6 | 4 | 0.2-0.4 |

| S01 | 8 | 6 | 0.2 | W102 | 8 | 6 | 0.5-1.0 |

| S10 | 6 | 4 | 0.3-0.8 | W102 | 9 | 6 | 0.3-1.5 |

| S10 | 8 | 6 | 0.2-1.0 | W103 | 12 | 8 | 0.2-2.5 |

| S11 | 8 | 6 | 0.3-1.6 | W104 | 15 | 10 | 0.5-3.8 |

| S11 | 11 | 8 | 0.7-1.1 | W105 | 20 | 14 | 1.0-5.7 |

| S11 | 11.5 | 8 | 0.4-2.0 | W106 | 25 | 18 | 3.0-9.0 |

| S11 | 13 | 10 | 0.4-2.6 | W107 | 30 | 22 | 7.7-12.0 |

| S11 | 15 | 13 | 0.4-2.8 | W108 | 35 | 25 | 6.0-15.0 |

| S11 | 16 | 13 | 0.3-3.2 | W109 | 40 | 27 | 10.3-16.5 |

| S11 | 16 | 14 | 0.4-2.8 | W110 | 50 | 30 | 14.4-19.4 |

| S11 | 17.9 | 15 | 1.5-3.0 | W111 | 60 | 35 | 18.5-27 |

| S11 | 18 | 15 | 2.8-5.7 | W112 | 70 | 40 | 24.5-31.5 |

| S11 | 19 | 16 | 1.8-5.9 | V | 15 | 13 | 0.6-3.9 |

| S11 | 20 | 17 | 1.2-5.4 | V | 19 | 17 | 1.8-6.8 |

| S11 | 21 | 17 | 1.6-5.7 | V | 23 | 19 | 4.9-5.1 |

| S11 | 22 | 18 | 1.5-7.5 | V | 25 | 20 | 5.7-7.7 |

| S11 | 25 | 17 | 6.0-8.0 | V | 30 | 21 | 8.2-11.5 |

| S11 | 30 | 20 | 9.0-10.0 | E | 15 | 13 | 1.8-2.8 |

| S12 | 8 | 6 | 0.4-0.8 | E | 19 | 17 | 3.3-3.6 |

| S12 | 13 | 8 | 0.4-2.3 | E | 20 | 17 | 3.0-5.5 |

| S12 | 16 | 10 | 0.8-3.0 | A | 10 | 8 | 0.3-1.0 |

| S12 | 20 | 12 | 1.0-5.0 | A | 12 | 10 | 0.2-1.8 |

| S12 | 22 | 14 | 4.2-5.7 | A | 14 | 12 | 0.4-2.3 |

| S12 | 22 | 16 | 6.4-8.0 | A | 16 | 13 | 0.6-3.0 |

| S12 | 26 | 16 | 6.4-8.0 | A | 20 | 17 | 1.0-4.8 |

| R4 | 12.7 | 11.4 | 2.2-3.8 | A | 25 | 20 | 2.3-6.2 |

| R5 | 16 | 15 | 1.2-3.1 | A | 25 | 21 | 6.5-8.5 |

| R6 | 18 | 17 | 1.5-4.6 | A | 30 | 24 | 3.8-9.7 |